Air-tightness detector

Air-tightness detector

Product Name Multi-channel airtight tester / 500 (W)× 302 (D)× 700(H)

Product Number 60.02.002.0070

Product Description

Multi-channel airtight tester consists of two parts: control circuit and pneumatic circuit. Used for sealing test of shell products such as RRU.

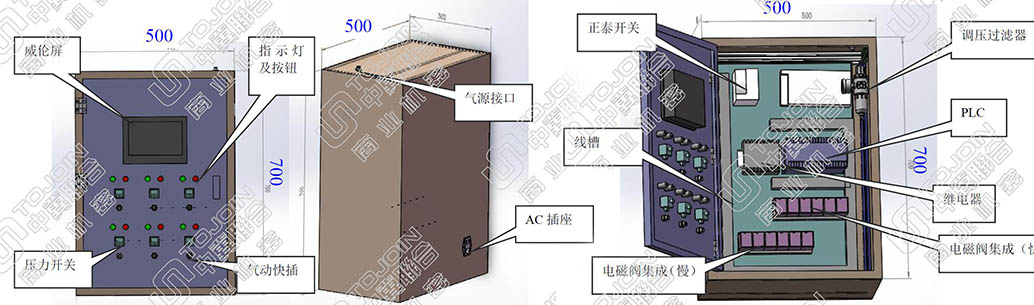

Product Appearance

Box structure

◆ The frame is welded by 20*20 square and the surface is painted white.

◆ Each surface adopts 1.5mm sheet metal processing, folding C-type side, the surface is painted beige white; all surfaces except the door are required.

◆ Screws are used to lock the four corners and require disassembly.

◆ The intermediate partition is the electronic control element lock plate, and the processing method is the same as above.

◆ Openings are required on the door. The hole size is shown in the diagram, with a dark lock.

◆ Rubber mat at the bottom, optional.

◆ The leaflet needs to use high-quality products, requires beautiful appearance, and does not weld.

◆ All screws adopt hexagonal head cap screws.

Skill requirements

1、aeration

1) Use single-channel test and 6-channel simultaneous test channel to set fast and slow charge two-way inflation.

2) After start-up, quick charge begins and the pressure stops when the barometric pressure reaches P-2.

3) After the fast charge stops, the delay time is 1-2 milliseconds (the time may be arbitrarily modified on the touch screen), and the slow charge begins. When the pressure reaches the barometer P-1, it stops.

2、Pressure maintaining

1) For a single test channel, after the barometric pressure reaches the P-1 value of the barometer, the pressure is maintained and timed (in seconds). The touch screen displays the timing value.

2) When the time reaches the holding time, the current pressure value is greater than the value of P-2. The test is OK and the touch panel flashes the OK indicator (the green light of the front panel of the cabinet flashes at the same time).

3) The time is less than or equal to the holding time, the current pressure value is less than the value of P-2, test NG, touch screen flashing NG indicator (and the red indicator light on the front panel of the box is flashing at the same time).

3、Functionality

1) Testing with a sealed container must have no significant pressure drop to ensure good air tightness of the device itself.

2) Status display: The status of each channel can be displayed at the same time on the touch screen/chassis. Counting of each channel's good product and NG product can be performed on the touch screen. The dwell time can be set.

3) The operation mode adopts 6 channels to be independent and 2 types of simultaneous operation. The single-channel operation can be operated simultaneously on the touch panel and the chassis panel. The 6-channel operation can only be operated on the touch panel.

4、Communication method Need to have a network interface to facilitate data upload.

5、Data record There are good and NG products count.

6、Switch control There is an air switch in the electric control box and a ship type power switch behind the equipment.

7、Environmental conditions

Working temperature: -5°C~+35°C Storage temperature: -25°C~+70°C

Relative humidity: ≤90%RH (temperature 40±2°C) Atmospheric pressure: 86kPa~106 kPa

Technical Specifications

Working power | AC220V(50HZ) |

Atmospheric pressure | 86kPa~106kPa |

Interface type | RS422,Ethernet |

Control method | Push button switch control |

Safety protection measures | Leakage switch |

Working temperature(°C) | Normal temperature work -5°C~+35°C |

Relative humidity | ≤90%RH(Temperature40±2℃) |

Appearance dimension(mm) | 500(W)*302(D)*700(H) |

Weight(kg) | About 37.5 |

Appearance of color | The main body is beige and the bottom cover is light blue (according to customer requirements) |